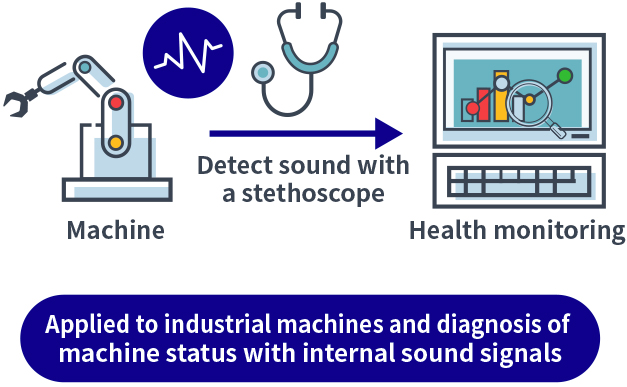

calculating production performance and detecting various situations

such as unexpected system down and checking product quality through

AI deep learning analysis using sound data.

In the past, Specialized personnel or embedded applications

such as complex machines were required for monitoring machines.

Now, With various AI voice recognition technologies,

It’s possible to detect unusual signals in sound data

made by factories and machines.

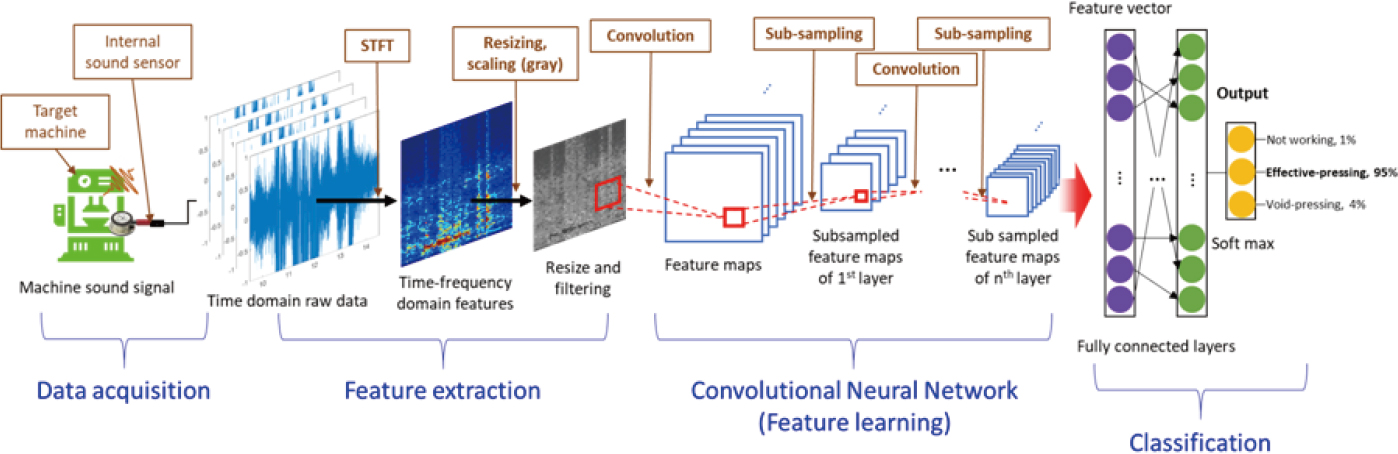

System diagram

Monitoring equipment operation status, Determining its lifespan,

Checking defective products through deep learning analysis using sound sensors.

· Sound Analysis - Analysis of phenomena, predictions, and causes → Detection of equipment abnormalities

·Regression Analysis - phenomenon, optimization, cause analysis → facility lifecycle management and optimization operation

▲ Algorithm conceptual diagram – After featuring sound data with SFTP, the filtered data will be processed by CNN for deep learning.

The classified result will be used for determining valid production performance and equipment status.

Main Features

Real-time status monitoring for production

(operating time, maximum/actual production quantity),

and replacement related information.

Provision of facility management, mold management,

mold parts management, mold removal/installation history,

number of strokes by mold, production status

System features

-

01

Real-time monitoring

of machine

equipment status -

02

Early detection of

system anomalies -

03

Strategic utilization of

robot/facility data -

04

Reduce

unnecessary

maintenance costs -

05

Prevent accidents by

increasing system

safety and reliability

Benefits

-

01 Notification for maintenance schedule according to facility operation rate.

-

02 Automatic facility status detection and notification.

-

03 Flexible, Fast, and scalable data processing

-

04 Automatic data-based crash prediction.

-

05 Saving cost for pre-detection