Bigbran-T is a real-time defective product detection/tracing and total

quality management solution based on ICT by collecting thermal

image data and inspecting the distribution and pattern of its influence

factor making it able to achieve “Zero Defects” during the production process

quality management solution based on ICT by collecting thermal

image data and inspecting the distribution and pattern of its influence

factor making it able to achieve “Zero Defects” during the production process

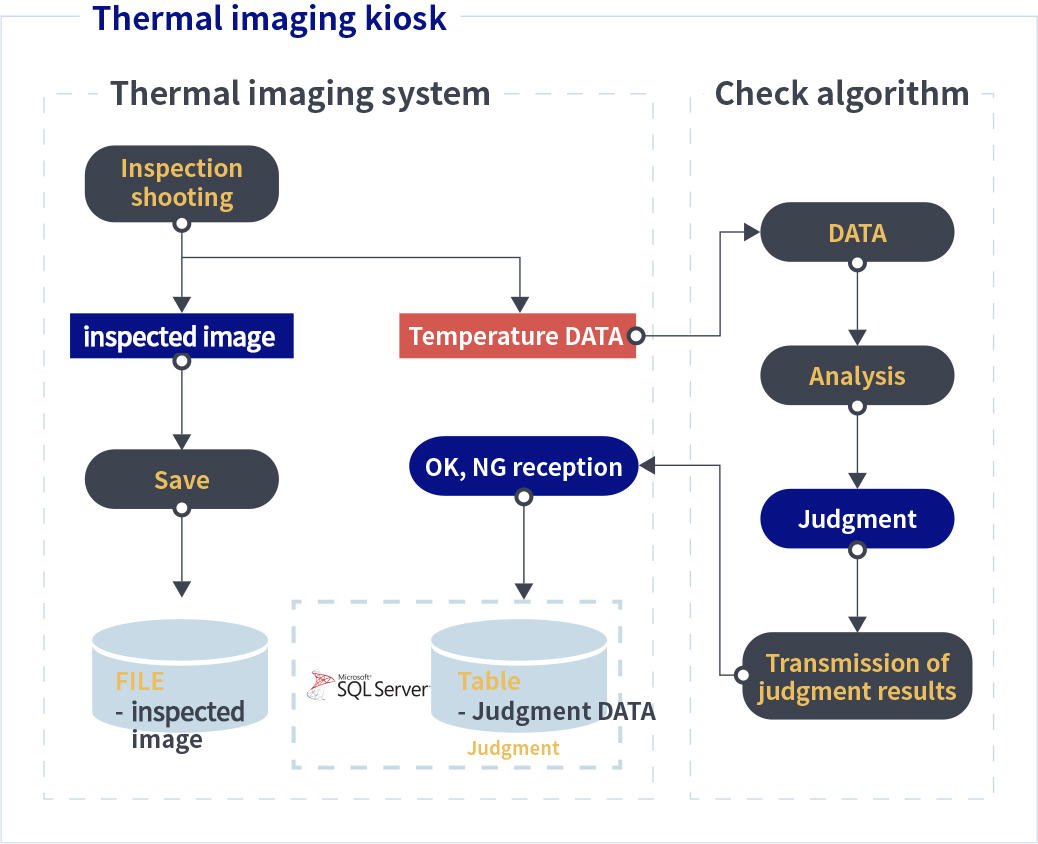

System Diagram

Main Features

-

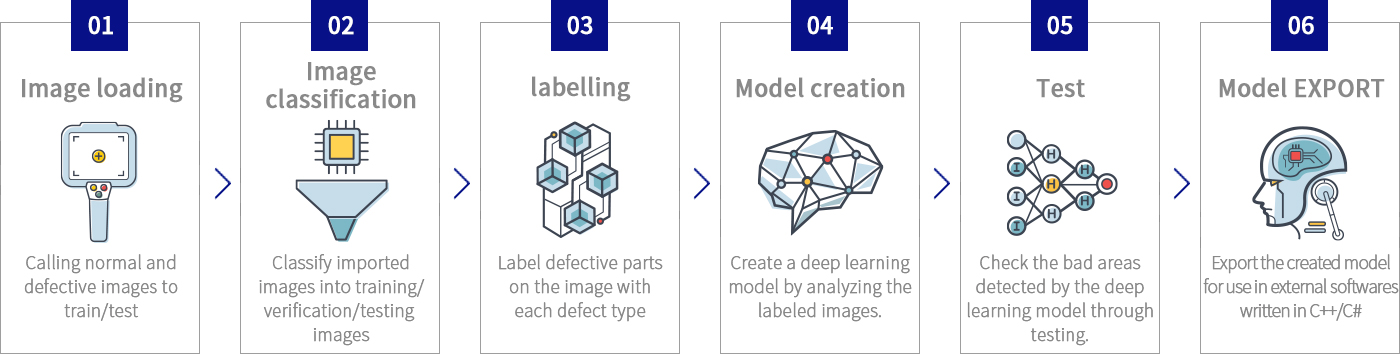

TQIS -Thermal imaging Quality Inspection SystemTQIS Feature provides product quality information detecting defective

products in real-time by thermal image data from production process -

TPTZ - Thermal Imaging Quality Tracking SystemTPTZ Feature allows a smart production process quality management

system by providing the production process information to a quality control

manager to provide an environment for intergrated management of product

inspection and pass/fail judgement. -

TBAS - Thermal Image Quality Analysis SystemTPTZ Feature provides ability to detect and collect/manage defective factors

from the production process.

Benefits

-

01

Quality issue prediction using

deep learning algorithms -

02

Real-time Image, data for

determining defective

products -

03

Provision of defect judgment

data with due diligence -

04

History management

System expected effects

-

01 Securing reliability by accumulating information

01 Securing reliability by accumulating information- Securing detection reliability by improving defect detection rate

- Accumulation of real-time quality inspection results and inspection information

-

02 Minimize loss by recognizing anomalies

02 Minimize loss by recognizing anomalies- Minimize opportunity cost caused by false defective product detection and its shipment

- Anomalies recognition.

-

03 Securing a system through real-time monitoring

03 Securing a system through real-time monitoring- Real-time process status monitoring

- Achieve management system

-

04 Cost savings through defect-free realization

04 Cost savings through defect-free realization- Reduced Q-Cost

- Archieve ZERO DEFECTS